Bulkhead vs Passageway Lights: 9 Costly Mistakes to Avoid

Bulkhead vs passageway lights is a common question in marine refit projects, shipyard maintenance, and even industrial-style décor builds. The two are often confused because both are rugged, protective fixtures designed for harsh environments—but they’re not the same thing. Choosing the right one affects safety, compliance, glare control, installation time, and long-term maintenance.

What Bulkhead Lights Are

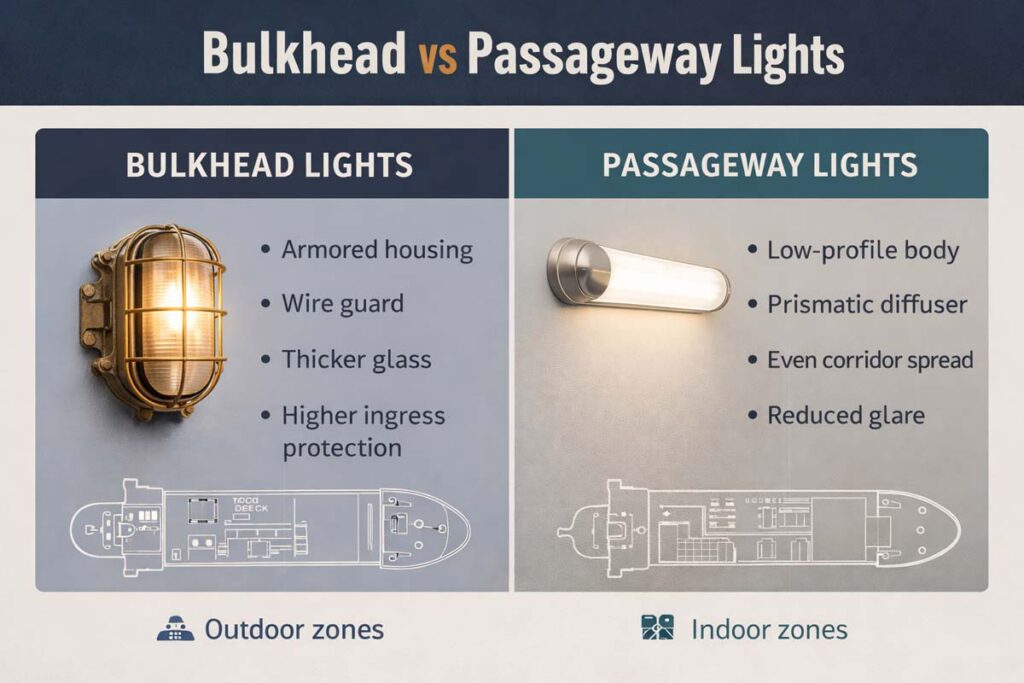

A bulkhead light is a heavy-duty fixture designed to mount directly onto a bulkhead (a ship’s vertical partition/wall) or other structural surfaces where impact, spray, vibration, and corrosion are expected. Bulkhead lights are usually:

- Caged or guarded (wire cage or cast guard) to protect the lens

- Built with thick housings (cast aluminum, brass, gunmetal, or steel)

- Sealed to resist water intrusion, dust, and grime

- Used both indoors and outdoors depending on rating and construction

Want something that feels authentic without looking overdone? Explore our nautical ship lighting options for pieces with real maritime character.

Why they exist

Bulkhead lights are “survival” fixtures—made to keep working in rough service areas, wet zones, and places where gear, hoses, tools, or movement could damage lighter fittings.

What Passageway Lights Are

A passageway light is intended primarily for corridors and walkways—spaces where people move frequently and need consistent, glare-managed illumination for safe navigation. Passageway lighting tends to:

- Be more streamlined than bulkhead fixtures

- Provide even light distribution along a corridor

- Reduce glare and harsh shadows

- Prioritize visibility and wayfinding (especially at night or during reduced lighting conditions)

Depending on vessel type, passageway lights may be wall-mounted, ceiling-mounted, or recessed/low-profile—built for durability, but generally with a stronger emphasis on controlled beam spread rather than maximum impact protection.

Bulkhead vs Passageway Lights: Key Differences

Here’s the practical breakdown that matters when you’re sourcing, repairing, or upgrading ship lighting.

1) Primary purpose

- Bulkhead light: Protection + endurance in harsh zones

- Passageway light: Safe, comfortable corridor illumination

2) Typical build and protection

- Bulkhead light: Often has a cage/guard, thicker lens, heavier body

- Passageway light: Usually sleeker, sometimes still guarded but less “armored”

3) Light distribution

- Bulkhead light: Can be more directional or “hot spot” depending on diffuser

- Passageway light: Designed to be uniform, spreading light along the walkway

4) Installation location

- Bulkhead light: Mounts on walls/structures in work areas, exposed decks, wet rooms

- Passageway light: Mounts along corridors, stair towers, accommodation routes

5) Maintenance expectations

- Bulkhead light: Built for fewer failures in punishing conditions; may be heavier to service

- Passageway light: Often easier access for routine bulb/LED driver swaps (design varies)

Where Each Light Is Typically Used on a Ship

Common bulkhead-light locations

- Engine room entrances and service corridors

- Deck areas exposed to spray and weather

- Pump rooms, workshops, and machinery spaces

- Cargo access routes where impact risk is high

- Exterior bulkheads and superstructure areas

Common passageway-light locations

- Accommodation corridors

- Stairways and landings

- Bridge access corridors

- Crew routes connecting living quarters to muster points

- Interior passageways where glare control matters

Rule of thumb: If the space is harsh, wet, or impact-prone, bulkhead-style protection usually wins. If the space is a long corridor where people move constantly, passageway distribution usually wins.

Materials, Lens Types, and Protection Features

When buying marine salvage lighting (or matching existing onboard fixtures), materials and lens choices matter as much as “bulkhead vs passageway.”

Housing materials

- Brass / gunmetal: Excellent corrosion resistance, classic marine look, heavy-duty feel

- Cast aluminum: Common on commercial vessels; lightweight, durable, often coated

- Steel / iron: Strong but must be protected (paint/coating) to resist corrosion

- Stainless steel: Good corrosion resistance, more modern appearance

Lens and diffuser options

- Frosted glass: Better glare reduction (great for passageways)

- Clear glass: Maximum brightness, more glare risk

- Prismatic glass: Spreads light more evenly; common in corridor fixtures

- Polycarbonate (in some modern units): High impact resistance, but verify heat/UV suitability

Guards and cages

Bulkhead lights frequently include:

- Wire guards

- Cast protective grilles

- Reinforced frames with thick gaskets

These features are valuable in high-traffic industrial zones where accidental knocks are common.

Mounting, Wiring, and Retrofit Considerations

Mounting differences

- Bulkhead lights: Often surface-mounted with robust flanges and heavier fasteners.

- Passageway lights: May be surface-mounted or low-profile; some are designed for clean corridor aesthetics.

Wiring and voltage notes

Ships may have lighting circuits different from standard building systems. Common realities include:

- Mixed voltage environments depending on vessel and era

- Different earthing/grounding practices

- Older fixtures originally designed for incandescent lamps

If you’re upgrading to LED, check:

- Driver compatibility (voltage range and frequency)

- Heat management inside sealed housings

- Space for LED modules without compromising gasket seals

Retrofit tip for salvaged fixtures

For reclaimed marine lights used in buildings (restaurants, hotels, homes):

- Convert the wiring safely to local code (UL/CE/IEC considerations depend on country)

- Preserve original housings while replacing internal components

- Keep gaskets and strain reliefs intact for safety and longevity

Marine Safety and Compliance Notes

Lighting on working vessels can fall under safety requirements depending on location (escape routes, emergency lighting zones, hazardous areas). A few important cautions:

- Hazardous area (Ex/ATEX) locations require certified fixtures—don’t assume a heavy bulkhead light is explosion-proof.

- Emergency egress routes may require specific illumination levels, signage integration, or backup power.

- Ingress protection (IP) and corrosion resistance matter in wet zones.

If you’re sourcing salvage fixtures for active service, treat compliance as a verification step: confirm ratings and suitability before installation.

Quick Buyer Checklist

Choose a bulkhead light if you need:

- High impact resistance (tools, traffic, gear)

- Strong sealing against spray/dust

- Outdoor or wet-room durability

- Rugged, protected lens design

Choose a passageway light if you need:

- Even corridor lighting with reduced glare

- A cleaner profile along walls/ceilings

- Comfortable brightness for frequent foot traffic

- Better distribution over long, narrow spaces

For either type, confirm:

- Mounting footprint and bolt pattern

- Lens condition (chips, cracks, hazing)

- Corrosion status and coating integrity

- Internal wiring condition and safe retrofit plan

- LED upgrade approach (module/driver space and heat)

FAQs about Bulkhead vs Passageway Lights

Are bulkhead lights and passageway lights interchangeable?

Sometimes—but not always. A bulkhead light can illuminate a corridor, but it may create glare or uneven hotspots. A passageway light can work on a bulkhead, but it may lack the guarding and sealing needed for harsh zones.

Which one is better for outdoor decks?

Generally bulkhead lights, assuming the fixture is suitable for exterior exposure and properly sealed. Outdoor locations demand corrosion resistance and protection from spray and impact.

What’s the difference between a “bulkhead light” and a “weatherproof light”?

“Bulkhead” describes a common marine style and mounting use. “Weatherproof” describes performance—resistance to water/dust ingress. Many bulkhead lights are weatherproof, but not all; the sealing and condition matter.

Can I convert salvaged marine lights to LED?

Yes—many restorers do. The key is selecting a compatible LED solution (voltage/driver/heat) and preserving safe wiring practices and seals.

What should I look for when buying reclaimed bulkhead or passageway fixtures?

Check lens condition, gasket integrity, corrosion, mount points, and internal wiring. If the fixture is meant for active marine use, verify ratings rather than assuming.

Conclusion

Bulkhead vs passageway lights comes down to environment and lighting intent. Bulkhead lights are built for protection and punishment—ideal for wet, exposed, or impact-prone areas. Passageway lights are built for safe navigation and uniform corridor visibility, reducing glare and improving comfort for high-foot-traffic routes.

If you’re sourcing reclaimed marine lighting, match the fixture to the zone, confirm condition and material suitability, and plan upgrades (especially LED) with safety and compliance in mind.