Brass Vs Aluminum Ship Lights: 7 Hard Truths Before You Buy

Brass vs aluminum ship lights comes down to three things you can feel in your hands: weight, corrosion behavior, and how much maintenance you want to live with. Brass brings the classic marine look, solid threads, and a warm patina that suits restorations. Aluminum brings lighter weight, easy handling on thin panels, and modern finishes like anodizing and powder coat. In this guide I will compare both materials the way we do in a workshop: what fails first, what lasts, what is worth servicing, and what to check before you bolt a light onto a salty deck.

What “brass” and “aluminum” really mean on marine lights

A ship light is not only the housing. It is a system: housing, lens, gasket, fasteners, cable gland, lamp holder, and the mounting surface.

Brass housings are usually copper-zinc alloys. Marine-grade brasses often add a little tin to reduce seawater problems like dezincification.

Aluminum housings are usually marine-friendly alloys (often 5xxx or 6xxx series) with protective finishes. Bare aluminum can corrode in salt conditions, so builders rely on coatings and anodizing to slow that attack.

If a seller cannot tell you the alloy or the finish, treat it as “unknown metal” and inspect harder. If you’re building a cohesive theme across rooms, it helps to start from the main ship lighting fixtures page and work outward from there.

Weight and mounting stress

If you have ever installed a heavy light on a thin cabin side, you already understand this section.

Aluminum is much lighter than brass by basic material density. Aluminum sits around 2.7 g/cm³, while common brasses are typically around 8.4 to 8.7 g/cm³.

That difference matters when:

- You mount lights on fiberglass or thin steel plates that can flex.

- You hang a passageway light from an overhead or bracket.

- You are trying to reduce vibration and “working” of fasteners.

Brass weight is not always a problem. On a heavy steel bulkhead, a solid brass body can actually feel more stable and less prone to ringing or rattling.

Corrosion and the salty reality

Brass: patina is normal, dezincification is the danger

Brass naturally darkens and develops a protective-looking surface layer. Many owners love that aged finish.

The real risk is dezincification, where zinc leaches out of certain brasses in chloride-rich environments like seawater. This can leave a weaker, porous copper-rich structure under the surface. Copper Development Association guidance notes that brasses with higher zinc content can be susceptible to dezincification in seawater.

What it looks like in the field:

- Pinkish or reddish patches (copper-rich areas)

- Crumbly edges on threads

- Hairline cracking around thin sections

- “Good shine” on the outside but soft metal underneath

This is why marine buyers often prefer naval brass type compositions for fittings exposed to harsh marine conditions, because tin helps resist dezincification.

Aluminum: pitting and galvanic corrosion are the main enemies

Aluminum protects itself with an oxide film, but saltwater and stagnant moisture can drive pitting and crevice corrosion, especially under gaskets, paint breaks, or salt-packed seams. A marine corrosion overview of aluminum alloys notes that even “marine resistant” alloys can still corrode depending on design and service conditions.

A good finish changes everything:

- Anodizing thickens the oxide layer and improves corrosion and wear resistance, which is why it is widely used for marine hardware.

- Powder coat and marine paint systems help too, but chips and scratches must be touched up.

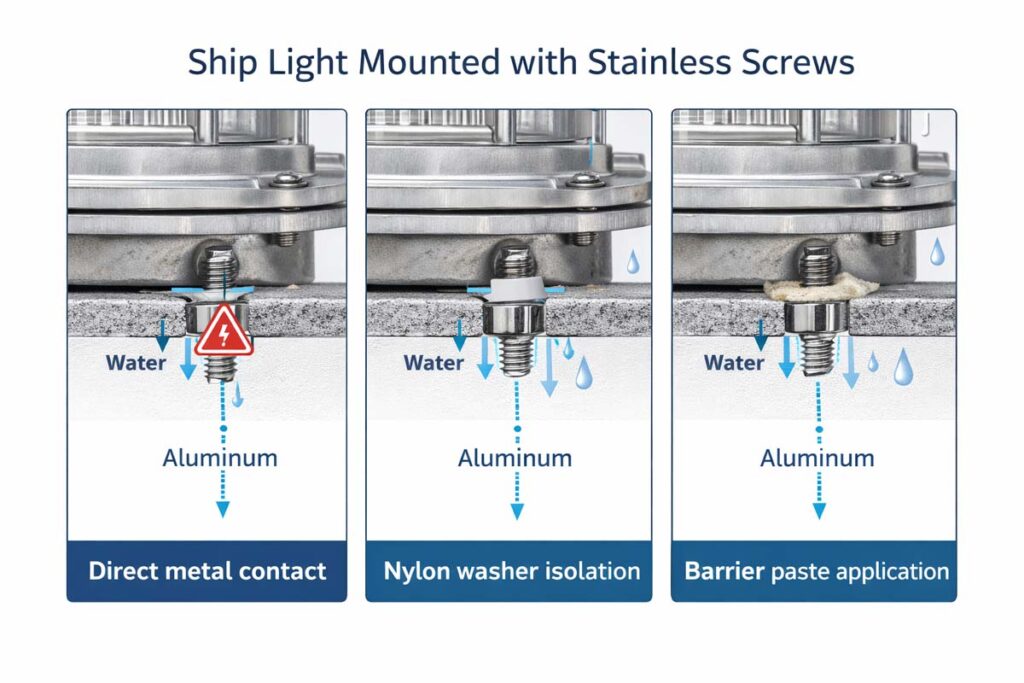

Galvanic corrosion: the hidden reason some “good lights” fail early

On boats, the housing metal is rarely alone. It touches stainless screws, steel structures, bronze fittings, and salty water.

When dissimilar metals are electrically connected in an electrolyte, the less noble metal corrodes faster. This is the basic galvanic corrosion mechanism described in galvanic series references.

Practical workshop advice:

- Aluminum + stainless fasteners + salt is a classic trouble combination if water sits in the joint.

- Brass next to aluminum structure can also create a galvanic couple, depending on contact area and wetness.

- Small screw heads into a large aluminum body is usually less risky than a large stainless bracket against a small aluminum boss. Area ratio matters.

If you want the light to last, isolate where you can: nylon washers, barrier paste, proper bedding, and correct fastener choice.

Heat handling and LED driver life

Most ship lights today are LED retrofits or LED-ready housings. Heat still matters because LED drivers and boards hate high temperature.

Aluminum generally conducts heat better than many brasses, which can help pull heat away from LED components. Typical thermal conductivity tables show aluminum at higher conductivity values than common brasses.

What this means in real use:

- An aluminum housing can be a better heat sink for sealed LED assemblies.

- A brass housing is still fine for many LEDs, but it may run warmer if the design traps heat.

Do not assume “metal body” automatically means good thermal design. Look for internal contact between the LED plate and the housing, not an LED bulb floating in air.

Threads, fasteners, and serviceability

This is where brass wins a lot of loyal fans.

Brass:

- Feels forgiving on threads.

- Machines cleanly and is easier to chase and repair.

- Tolerates repeated opening for gasket changes and rewiring.

Aluminum:

- Threads can strip if over-torqued, especially in cast parts.

- Fasteners can seize if you mix metals and skip anti-seize.

- Corrosion under the screw head can “grow” and lock parts together.

If you maintain your lights yourself, brass tends to be more pleasant to service year after year.

Appearance: traditional patina vs modern finish

Brass gives you:

- Warm tone, classic marine character

- Natural darkening and patina

- Polished “yacht shine” if you keep up with it

Aluminum gives you:

- Clean modern look

- Consistent color when anodized or powder-coated

- Easier matching with white superstructure or modern rails

Neither is “better.” It depends on whether you want a living surface (brass) or a stable finish (aluminum).

Maintenance reality: what you will actually do

Brass maintenance (simple, but regular)

If you like bright brass, accept that salt spray will keep calling you back.

A practical brass routine:

- Rinse with fresh water and mild soap, then dry fully.

- Spot-clean oxidation with a non-abrasive metal polish if needed.

- Protect with wax or a suitable clear coat if you want slower tarnish.

- Inspect gaskets and cable glands every season, not only when leaks show.

Brass care guides commonly separate cleaning, polishing, and lacquer management as different tasks because each affects the surface differently.

Aluminum maintenance (less frequent, but more “finish-aware”)

Aluminum lights often look low-maintenance until the coating breaks.

A practical aluminum routine:

- Rinse salt regularly, especially around screw heads and seams.

- Check for paint chips, bare metal, or white powdery corrosion.

- Touch up coating damage early, before pitting spreads under the finish.

- Use compatible fasteners and an anti-corrosion barrier at joints.

If the light is anodized, protect the finish from harsh abrasives that can cut through the layer. Anodizing guidance for marine environments emphasizes its durability and corrosion benefits when applied correctly.

Buying checklist: what to inspect before you commit

Use this quick scan when you are buying salvage lights, refurbished units, or new housings.

Housing and structure

- Look for cracks around the mounting ears and cable entry.

- Check if the housing has sharp crevices that trap salt.

- Confirm the lens seat is flat and not distorted.

Corrosion signs

- Brass: pink patches, porous spots, crumbling threads (possible dezincification).

- Aluminum: white powder, pitting under gasket lines, bubbling paint.

Hardware compatibility

- Are the screws stainless, brass, or plated steel?

- Is there evidence of galvanic attack around fasteners?

Sealing

- Confirm gasket condition and material.

- Check the cable gland and strain relief. Many “leaks” start at the cable entry, not the lens.

Which should you choose? Practical recommendations

Choose brass ship lights when:

You want a traditional look, you open the light for maintenance, and you like hardware that can be serviced and repaired without drama. Brass also suits interior spaces, classic restorations, and installations where weight is not a concern.

Choose aluminum ship lights when:

You want lighter fixtures, you are installing on thin panels, and you prefer modern finishes that stay visually consistent with less polishing. Aluminum is also a strong option for sealed LED designs when heat management is done properly.

The tie-breaker most buyers miss

Pick the light that matches your mounting surface and fasteners. A great housing on a badly matched bracket will corrode faster than a “less fancy” light installed correctly. Galvanic corrosion is about the whole assembly, not the label on the metal.

Notes from our salvage yard workflow in Chittagong

At Marine Salvage & Antiques Enterprise, we have been sourcing ship lights since 2011 from Bangladesh ship breaking yards. In practice, the best long-life results come from:

- Restoring sealing surfaces properly

- Replacing tired gaskets and cable glands

- Matching fasteners to the housing metal

- Using barrier compounds on joints exposed to spray

Brass and aluminum can both last a long time, but only if the light is treated like marine equipment, not home décor.

FAQs about Brass vs Aluminum Ship Lights

Does brass always corrode less than aluminum on a boat?

No. Brass often tarnishes in a predictable way, but certain brasses can suffer dezincification in seawater conditions. Aluminum can perform very well, especially when anodized or coated, but it is sensitive to pitting and galvanic attack if water sits in joints.

Is aluminum “too cheap” for marine lights?

Not if the alloy and finish are right. Many marine applications rely on aluminum because it is light and works well with modern coating systems. The weak point is usually poor finishing, scratched coatings, or bad fastener pairing.

Which is safer for electrical grounding?

Both metals conduct electricity. The real safety factor is how the fixture is wired, sealed, and protected, plus correct bonding practices on the vessel. If you see corrosion inside the junction area, treat it as a safety issue and service it.